Client Overview

- Industry: Automotive Components Manufacturing

- Location: Bawal & Neemrana Industrial Belt

- Company Size: 450+ employees

- Hiring Need: Blue-collar and mid-level technical staff

The company partnered with Orbit Global HR Consultants to address critical hiring challenges impacting production.

The Problem

The client was facing serious workforce gaps that directly affected productivity and delivery timelines.

Key Challenges

- High attrition in shop-floor and technician roles

- Delays in meeting production targets due to manpower shortages

- Poor response from job portals for skilled manufacturing talent

- Internal HR team overloaded with hiring and compliance tasks

- Offer dropouts and last-minute candidate no-shows

📉 Impact:

- Production delays of 10–15% per month

- Increased overtime costs

- Pressure from OEM clients due to missed deadlines

The client needed a fast, reliable, and location-specific hiring solution.

The Solution Applied

Orbit Global HR implemented a structured, end-to-end recruitment strategy tailored to the manufacturing sector and the Bawal–Neemrana talent market.

Step 1: Requirement & Workforce Analysis

- Conducted plant-level discussions with HR and production heads

- Analyzed shift patterns, skill gaps, and attrition causes

- Reworked job descriptions to reflect actual shop-floor requirements

Step 2: Local Talent Mapping

- Built a location-focused candidate pool within 30–40 km radius

- Used local databases, referrals, and offline sourcing channels

- Focused on candidates with similar plant experience

Step 3: Pre-Screening & Skill Validation

- Telephonic screening for stability, shift readiness, and salary fit

- Skill matching against machine operation, quality, and safety norms

- Only interview-ready candidates were shared

Step 4: Interview & Offer Management

- Coordinated daily interview slots to avoid production disruption

- Managed salary negotiation and expectation alignment

- Actively followed up to prevent offer dropouts

Step 5: Post-Joining Follow-Up

- 30-day post-joining follow-ups with candidates and supervisors

- Replacement assurance support reduced hiring risk

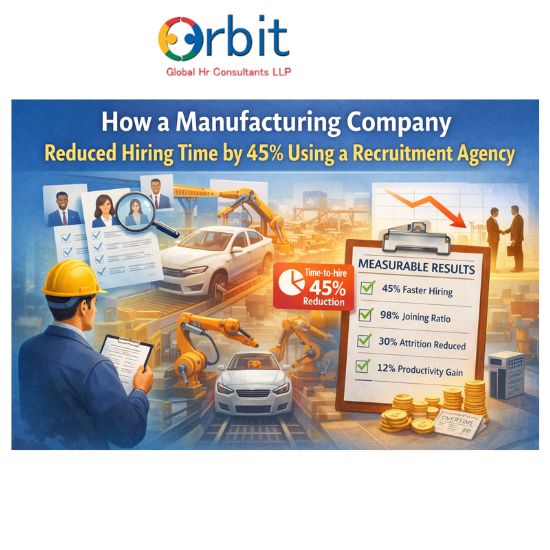

The Results (Measured Outcomes)

Within 90 days, the client achieved significant, measurable improvements:

Key Metrics

- ⏱ Time-to-hire reduced by 45%

- 👷 98% joining ratio (industry average ~80–85%)

- 🔁 Attrition reduced by 30% in critical roles

- 📈 Production efficiency improved by 12%

- 💰 Overtime costs reduced significantly

Business Impact

- Stable workforce during peak production

- Improved delivery commitments to OEM clients

- Internal HR team freed to focus on compliance and engagement

Why the Solution Worked

✔ Local talent expertise

✔ Manufacturing-specific recruitment knowledge

✔ Strong candidate engagement and follow-up

✔ Realistic salary and expectation alignment

✔ Structured hiring process, not volume-based sourcing

Client Feedback

“We were struggling to keep our production lines running due to manpower shortages. The recruitment support helped us stabilize hiring quickly and improved workforce reliability.”

Conclusion

This case study demonstrates how a well-planned recruitment partnership can directly impact:

- Productivity

- Cost control

- Workforce stability

- Business continuity

For manufacturing companies operating in industrial belts like Bawal, Neemrana, Rewari, or NCR, partnering with a specialized recruitment agency can deliver faster hiring and long-term operational benefits. Get direction

Leave A Comment